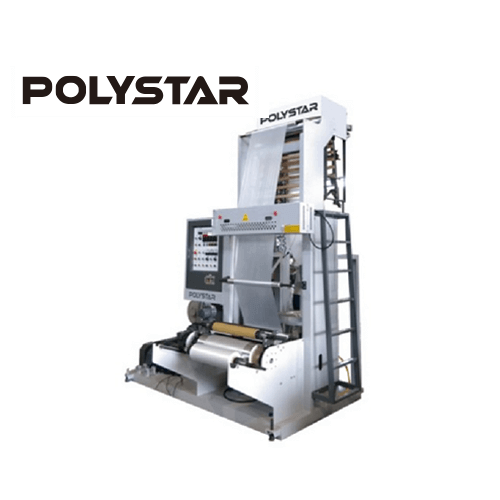

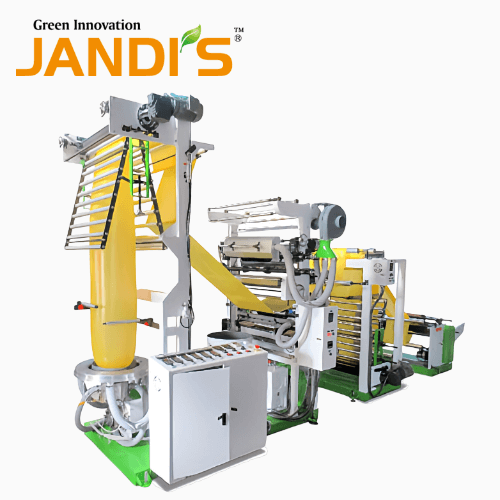

LDPE夾鏈袋印刷連線高速押出機(AEZ-45/55+ARP800i)

產品分類 : 吹膜押出機

LDPE ZIPPER BLOWN FILM MACHINE with ROTOGRAVURE IN LINE PRINTING MACHINE(AEZ-45/55+ARP800i)

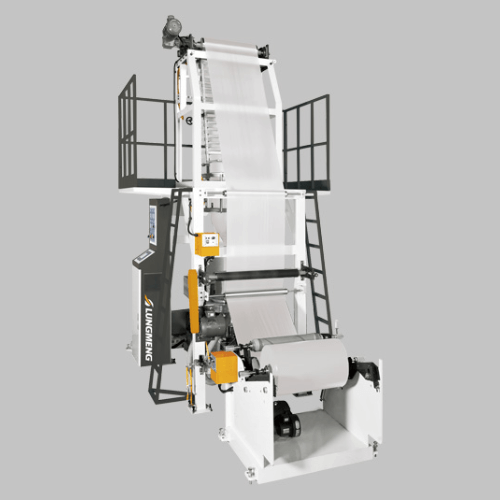

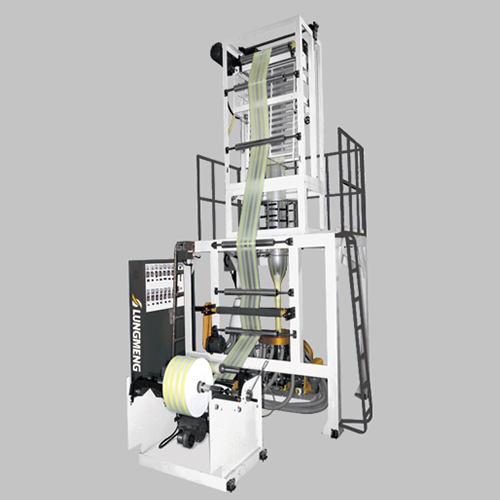

高速捆包膜保鮮膜吹膜機

產品分類 : 吹膜押出機

設計生產拉伸和保鮮膜具有高透明度和卓越的實力 雙站背靠背裝伺服驅動的微張力控制系統 在螺桿和機筒的高品質混合提供了良好的均勻性和高輸出 高性能空氣環設計,有效的冷卻 逆變器的交流電機,配有一致的生產量和可靠性 按照CE認證的龍盟機械標準 全封閉的自動微調回收系統(可選)

PVA水溶性吹膜機 - GF-AV35.45

產品分類 : 吹膜押出機

PVA base water soluble, compostable and biodegradable eco-friendly material

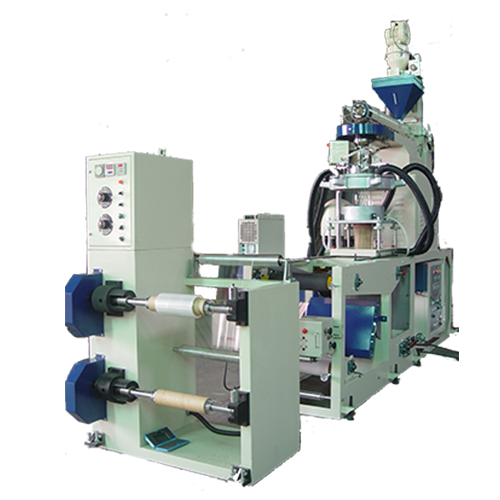

3 Layer Blown Film Machine for Shrink Hood Film

產品分類 : 吹膜押出機

3 Layer Blown Film Machine for Shrink Hood Film

電暈表面處理機 - T型 /吹膜機用

產品分類 : 吹膜押出機

電暈處理機是一種表面改性技術,用於改善附著力處理。 它使用低溫電暈放電等離子體來改變表面的特性。 塑料、薄膜、鋁泊、銅泊、電鍍膜(鍍鋁膜)、布料(紡織品)或紙張等材料可以通過電暈等離子體,以改變材料的表面能。 所有材料都具有固有的表面能。 表面處理系統幾乎適用於任何表面形式,包括3D立體物體、片材和卷材。 電暈處理是塑料薄膜、擠出和印刷加工行業廣泛使用的表面處理方法。 又稱塑膠表面處理機、塑料表面處理機、表面電暈處理機、大氣等離子、大電電漿、電暈放電處理、靜電處理機、塑料表面放電處理設備、電暈處理機、電暈處理裝置、放電機、電火花機。 應用 擠出/押出: .吹膜機 / 吹袋機 / ABA共擠 / Inflation machine .流延膜/片材擠出/擠出塗層/塗層層壓/擠出層壓/淋膜機 印刷: .連線印刷機/凸版印刷機/柔版印刷機/凹版印刷機/編織袋印刷/標籤印刷/溶劑印刷/水性印刷/背心袋印刷 複合與加工 .分切複捲機/塗佈/濕式貼合/乾式貼合/熱貼合/無溶劑貼合/分條機/複合機/塗膠機 機型 CH-800S / CH-1000S / CH-1200S / CH-1500S / CH-2000S / CH-3000S / CH-5000S CH-800T / CH-1000T / CH-1200T / CH-1500T / CH-2000T / CH-2KT CH-3000T / CH-5000T / CH-8000T CH-3KT / CH-5KT / CH-8KT / CH-10KT / CH-12KT / CH-15KT / CH-20KT CH-3KD / CH-5KD / CH-8KD / CH-10KD / CH-12KD / CH-15KD / CH-20KD 適用材料 HDPE, LDPE, LLDPE, MLLDPE, PET, PVC, PP, OPP, CPP, BOPP, PI, PS, PC, EVA, Nylon, PTFE, PU, TPO, TPE, TPO, 可分解, 可降解, 收缩膜 中空板, 瓦楞板, 萬通板 PE woven, PP woven, 編織袋,編織布 Metalized film, FPC, Foil, 鋁泊, 銅泊 Non woven, Melt blown, Fabric, textile, 無紡布, 不織布, 熔噴布

單層模頭用於HDPE或LDPE或PP

產品分類 : 押出模頭

+適用於 LDPE, HDPE及LLDPE吹袋機 +全部鋼材採用日本SCM-440鋼材 +低壓螺旋設計、高穩定性、高產能 +經精密嚴謹加工流程處理 +品質值得信賴

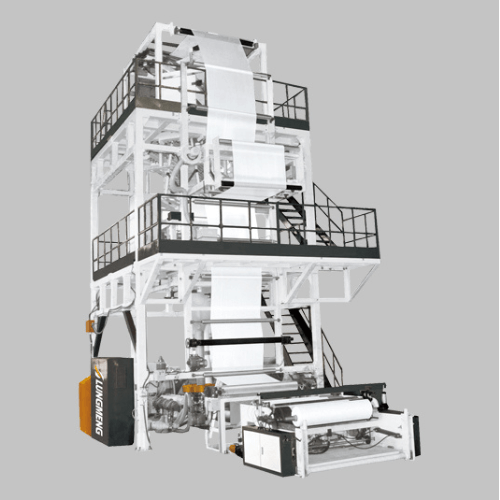

大型農業、地膜及工業用吹膜機

產品分類 : 吹膜押出機

The films is greatly helpful in agriculture and geomembrane. - Greenhouses that could increase the temperature to improve the growing environment and increase the available areas for planting, especially in high latitude and cold regions. - Mulch films could prevent the soil moist loss and preserve the temperature to keep soil warm that provide a suitable environment for seeds and sprout. - Silage films and stretch films is also more popular to store silage, hay and maize. - Geomembrane film could used to the construction for preventing leakage, water diversion for irrigation and reservoir and non-slip at side slope. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Opened film width range in 6 - 20 meters Designed output range 600 - 2000 kg/hr

三層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

ABA三層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

旋轉塔ABC三層膜吹袋機

產品分類 : 吹膜押出機

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements. The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die. Suitable for producing three-layer films for specific functions Recycled materials or CaCO3 is applicable to the middle layer in order to save material costs Die and air-ring specially designed for producing high-quality three-layer films 360° Oscillating Haul-off unit improves film thickness uniformity EPC (Edge Position Controller) Full customization according to your specific requirements

五層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

CT-DC系列雙色吹袋機

產品分類 : 共擠吹膜機

Equipped with 2 extruders, A/B type blown film machine is able to produce two layer/two colours film. This machine can produce two-color-striped films. Final products have obvious streak of two separate colors. Upgrade die and air ring to produce HDPE and LDPE 2 layer film.

FB 大型吹袋機

產品分類 : 吹膜押出機

Film width 2000 ~ 4000mm, for general packing and agricultural Hutch. Heavy duty construction, take up tower. Automatic surface winder with uploading device. Swing type manual screen changer. LDPE / LLDPE Heavy Duty Big Size Blow Film Machine. Screen changer of swing manual type. Extruding die of single spiral channel gives even and smooth flow pressure, Air ring of dual orifice design ensures ultimate cooling. Heavy duty steel structure takes up tower. EPC (Edge Position Controller) Fully automatic big roll type single winder or back to back auto winder.

高速單層膜吹袋機

產品分類 : 吹膜押出機

先進的螺桿設計和槽式給料機,材料混合比例良好,產量高,生產質量可靠。 獨特的模頭和風環吹出穩定氣泡,並產出更均勻的膜厚和更均勻的袋子。為T恤包,購物袋,農業等許多方面提供了一個很好的解決方案。 機器高度可調整。 特性 原料應用:HDPE / LDPE / LLDPE / EVA 高效率機器,能耗低但產量高。 高級齒輪箱帶強制潤滑系統和油冷卻器。 螺桿和料桶的混合性能好。 選配裝置 自動進料機 單層膜模頭與風環 A/A雙層膜模頭與風環 旋轉模頭 手動換網裝置 IBC (氣泡內部冷卻裝置) OBC 膜厚控制系統 Corona 表面處理機 壓花輪 雙收台 荷重元 連線柔版印刷機

PP薄膜吹袋機

產品分類 : 吹膜押出機

High Speed PP Blown Film Machine is suitable for producing PP bags and films. Special design of screw results in better mixing to ensure high output and good film quality. AC inverter control motor for energy saving. The water-quenched system effectively makes films glossier and more transparent, very suitable for food, flower and garment packaging. Also capable of producing multilayer films (Model: CTPP)

ABA吹膜生產線(JC-ABA系列)

產品分類 : 共擠吹膜機

JC-ABA系列為3層共擠的吹袋設備, 主要是以較低的生產成本生產高質量膜的最終解決方案。 ABA 3層共擠生產線由兩台高性能擠出機和3層ABA共擠模頭組成, 外層主要使用原始材料,而核心層則使用大量的CaCo3或內部回收的顆粒材料。此外,ABA 3層膜結構還具有比常規單層膜更高的強度特性,總體上給競爭市場帶來了優勢。

CT-ML系列吹袋機

產品分類 : 共擠吹膜機

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.

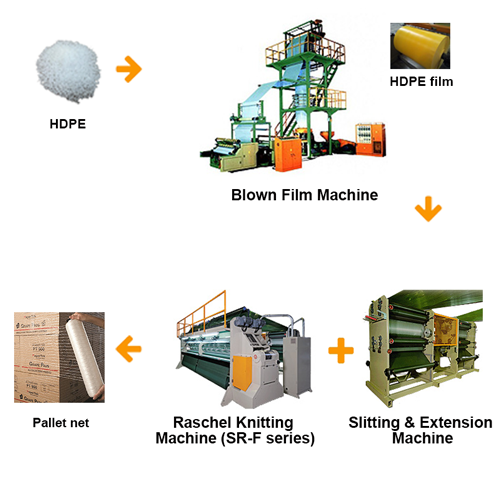

農業用膜及土工膜吹膜設備

產品分類 : 吹膜押出機

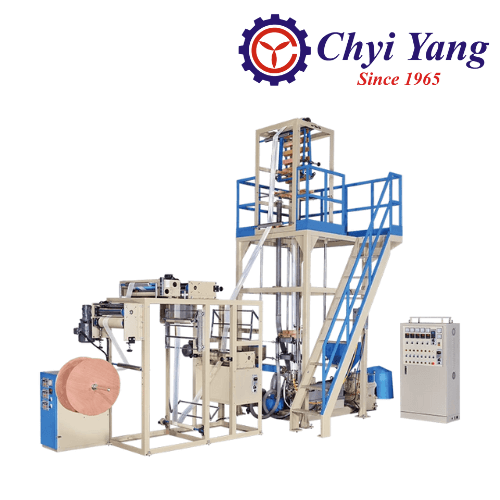

HDPE 單層系列吹膜生產線

產品分類 : 吹膜押出機

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

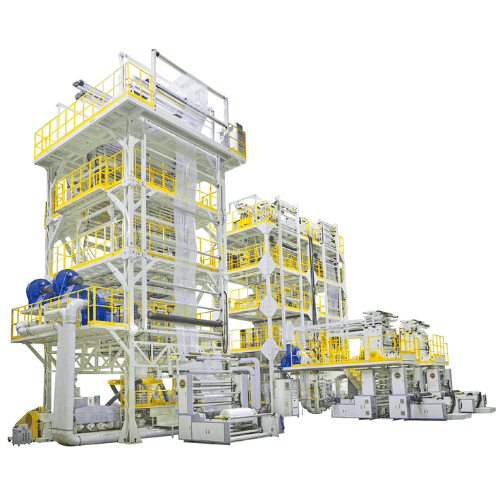

多層拉伸套膜吹膜機

產品分類 : 吹膜押出機

People replace stretch wrap film with stretch hood film. The stretch hood film has excellent holding force and extraordinary elasticity, so that it could cover the cargo tightly and prevent the stacked sacks from collapsing. It improves the security in logistic transportation greatly. Furthermore, it has high puncture resistance to protect the goods and provides good transparency that assist people to distinguish the content of cargo and to scan the labels. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Film width: 1500 ~ 1850 mm Output: 280 ~ 450 kg/hr